As CMO Geoff Stedman explains elsewhere in the blog, metadata is the fuel that drives supply chain activities, and metadata can come from a multitude of places. Technical metadata, whether from XML or JSON files, AWS SNS or AWS SQS, whether embedded or manually entered through a Rally Gateway, can drive decision-making and determine next steps in the supply chain.

Here we look in a little more detail at common functions in the supply chain driven by technical metadata.

Metadata can be extremely useful for validation purposes when, for example, the metadata is compared with metadata in an accompanying file. It is used to hold scheduling data and determine deliveries. It can store supply chain status as it progresses, or it can store errors that are raised along the way. If an asset runs through multiple supply chains — or even multiple times through the same supply chain — a certain amount of queue handling might be required to ensure data does not get overwritten or that processes such as transcoding or QC don’t conflict with each other.

Queueing Multiple Versions

Occasionally, a Rally media supply chain will receive incremental versions of a media file in quick succession, one right after another, and those versions need to be processed in the right order. In such cases, it is useful to employ a queueing mechanism using metadata. The metadata in the first version of media will be stored in a list of items that are in process, and if a subsequent version of that media arrives while the first one is processing, it will add its own metadata to a second list that becomes the queue. Once the first version of media finishes processing, it will check the queue list: if it finds items there, it will trigger the supply chain from the start using the metadata of the second media version. This can be applied to the whole supply chain, just certain parts of the supply chain, or both.

Some examples of metadata being used like this below:

Managing Metadata Manually

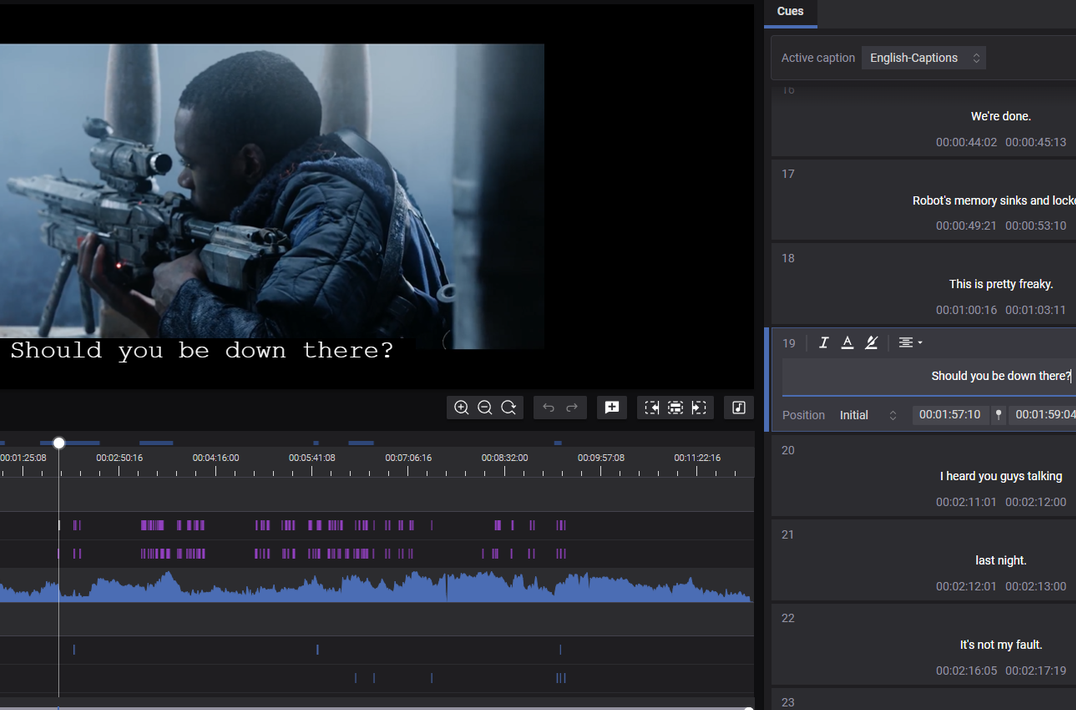

Some supply chains might require manual intervention from an operator to make decisions on next steps. One such case is when media metadata that was extracted from MediaInfo finds an unexpected value. A workorder is created, to be viewed by the operator, requiring them to make the best decision for the next step. In Rally Gateway, this workorder appears as a form with two sections of information relevant to the operator. The first section presents the media metadata extracted by MediaInfo, while the second section shows the expected required values from the JSON or XML that accompanies the media. From these sections, you can see whether those expected values match the extracted metadata.

The operator can quickly compare the two and locate mismatches between them, make any necessary corrections, and complete the workorder. From here, the supply chain resumes and continues with the appropriate step that the operator chose. A workorder and forms in Rally could look like this:

If SNS or SQS is utilized at certain points to drive the supply chain and communicate with a third-party application, the application may be required to respond back after the request is generated. In those instances, it is a good idea to associate the requests with a unique identifier and log them in metadata. This allows a record of the response to be maintained within the supply chain.

Reach out to your Solutions Team if you want to ensure you’re getting the most out of metadata in your Rally supply chains or want to explore new ways to achieve even greater intelligence and efficiency.