Work Smarter and Make Better Decisions to Extend Your Competitive Edge.

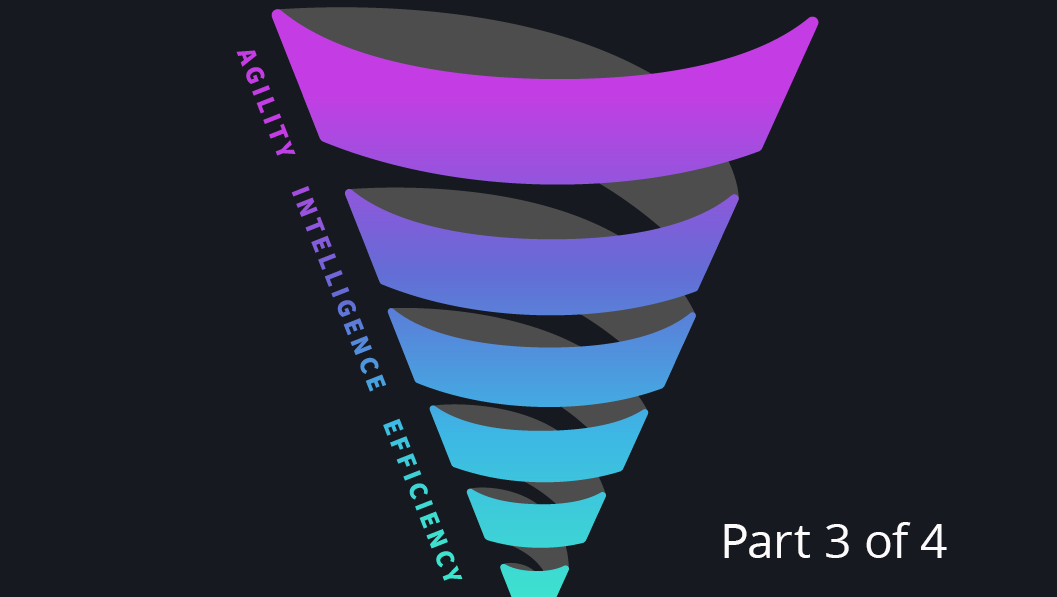

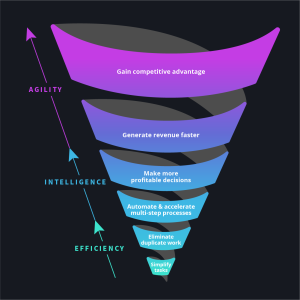

Every organization wants to do more with the resources it has. But how do you do more with resources that are already completely maxed out? The trick is to apply Intelligence — one of three pillars of media supply chain optimization along with Efficiency and Agility — to be smarter about how you use those resources. Using Intelligence, you can also start building automated multistep processes where each step of the supply chain builds on the work done before.

Earlier in this blog series, we talked about gaining efficiency through task simplification and the elimination of duplicate work. Those first two steps are critical to focusing resources on the job at hand and freeing up resources to handle more workload. But what if you could compound that value by having an upstream process provide intelligence that guides downstream processes? Or even helps you make smarter business decisions, and make them faster?

Automating and Accelerating Multistep Processes

In any supply chain, there will be a mix of machine-based tasks that can be automated and manual tasks that obviously cannot. Automated tools are great for the heavy lifting, making those processing tasks much faster and more efficient, provided they have been deployed on properly architected scalable infrastructure (more on that in a moment). These automated processes can also generate information (metadata) that can guide the manual tasks, making human operators more efficient and productive. The net effect is a reduction in the mundane tasks that need human processing. In a nutshell, accelerating multistep processes is all about leveraging the logic of the supply chain to free people up to do more.

The word “accelerating” is important here because time-based metadata generated from automated processes doesn’t just refocus people on those tasks requiring human attention; it guides people straight to the points of interest they need to address, facilitating faster-than-real-time completion of those manual tasks. Human intervention becomes a matter of involvement by exception rather than the default of touching every piece of content. Automated processes can handle the vast majority of the work needed, with additional automated tasks inspecting the results to flag anything that might need attention. Moving human involvement to an exception basis dramatically improves productivity and increases the content throughput flowing through the supply chain. Providing data that people need to make better, faster decisions — decisions that keep the larger supply chain humming — supply chain optimization with metadata intelligence can drive the workflow forward.

In some cases, automated decision-making can be used to deal with problems that repeatedly and unnecessarily require human attention. One Rally user recognized that content from a particular supplier had caused a transcoding job to fail on repeated occasions. Rather than have staff spend time to sort out the problem again, he built a rule that automatically ensures any content from that supplier is sent to a different tool.

Another benefit of moving to machine-based media processing is the opportunity to parallelize your processes. By refocusing or removing human involvement in standard repetitive processes, you can take advantage of automated decision-making to elastically scale the processing infrastructure to meet the job demands. When you’ve reached this point, you can turn a series of very linear steps into processes that occur in parallel.

With a conventional on-prem model, you are fundamentally limited by the amount of infrastructure underpinning your operations. But with the abstraction of infrastructure, provisioned in the cloud as and when you need it, those limitations don’t apply anymore. And here is where the advantages of the cloud really come into play.

You can automate, accelerate, and parallelize, scaling up your productivity. You can also burst, spinning up resources — services running on virtualized infrastructure — to take on a big deal or high-volume job. Perhaps you’ve suddenly got a huge pile of content to process. Because your multistep processes are automated, you need only run it through a bigger “factory.” You scale up that factory to accommodate volume, time, and quality parameters, and then you scale right back down again.

In the past, taking on similar work would have required scaling up physical infrastructure and hiring and training a team of people. You’d spend a lot of time and money — and you’d never be quite sure exactly where you spent it. Not with your optimized cloud-based media supply chain, thanks to another important aspect of Intelligence: cost visibility.

Driving Profitability with Cost Visibility

Intelligence from across the media supply chain can yield unique visibility into the cost of your supply chains, down to the unit level. You know exactly what it’s going to cost to scale up your media factory and how much time it’s going to take to handle any new job. You can predict the impact of a burst on cost and make a better decision about whether to take on a job or pursue a new deal. If, for example, you’re considering licensing a new library of content to add to your portfolio, you’ll know in advance what it will cost you to get that content ready.

Because many media organizations lack this visibility, their best estimate of the cost to run a channel might be total capex divided by the number of channels being run. Both the business model and physical infrastructure make it difficult to pin down unit costs for every single function involved in content preparation and delivery. But the cloud-based media supply chain, with its unique consumption-based pricing model, allows you to capture this kind of cost data across the entire workflow.

In today’s competitive and quickly evolving media landscape, this knowledge is a game-changer — and often a key reason that organizations adopt the SDVI Rally platform. With this data, you have the metrics to determine the cost of preparing content or running a particular channel. You have access to predictive data that you can apply to future business decisions. Rather than guess as to whether a particular decision will make your company money, you know in advance!

It’s not just about picking the right deals and knowing how they will affect your bottom line. You also have the means to modulate infrastructure and processing costs based on expected revenue or the required deadline. When you can add up and see the bill of materials for the creation of a certain product, you can look at specific areas, such as QC or transcoding, to see if those costs make sense, or if you could do better using a different tool.

In fact, you might choose to apply different tools based on the value of the content. For a high-value piece of content that will be played out in prime time, you likely will apply a high-end transcoder to put that content into the right format. For an infomercial running at 2 a.m., you might choose a lower-cost transcoding tool. For the first time, you can make unit profitability decisions.

This practice is fairly standard in manufacturing, where predictability is critical to profitability. Rally brings that predictability (and profitability) to the media business, telling you what your costs will be before you move forward with a new product or service.

While this visibility is vital to decision-making when it comes to new business opportunities, it can also foster greater accountability within a media organization and across various departments. For the first time, unit cost visibility also means that the cost and time of every step in a supply chain is understood, improving department-level budgeting and cost accounting.

Summary

Using a cloud-based media supply chain optimization platform to gain a much deeper understanding of costs, as well as the ability to modulate those costs depending on parameters such as content value, your organization can make more profitable decisions, and make those decisions faster.

Speaking of faster … in the next blog in this series, we’ll explore how this capability fuels faster time to revenue and delivers the Agility essential to maintaining a competitive advantage.

Read the final post in this series, “The Optimization Endgame“.