A practical framework for quantifying the cost of the status quo and the value of change

In a recent post, I wrote about how maintaining the status quo across media operations can wind up costing more than a strategic shift toward cloud-enabled orchestration and automation of the media supply chain. Feedback on the blog tells me that many media professionals recognize that by standing still, their organizations will compromise agility, efficiency, and opportunity over time. They know, intuitively, that their supply chains are too manual, too fragmented, and too slow to adapt. What’s less obvious is how to turn that intuition into a persuasive business case for moving forward with media supply chain transformation.

While “transformation” may seem to suggest a massive, all-at-once shift, the reality is that some of the strongest business cases start with a single workflow and a surprisingly simple set of measurements. Let’s take a closer look!

Measuring the Status Quo

The first and most important step in building a credible business case is to document current operations, clearly and in detail. Why? Because before you can justify change, you need to understand the cost of the current state.

Workflows evolve organically over time. Manual steps are added. Exceptions become the norm. Information is duplicated across spreadsheets, emails, and a variety of systems. When you expose these inefficiencies across your operations — or even a single process — they become difficult to dismiss.

Working with various media organizations over the years, we’ve seen that one highly effective approach to building a business case is to take a defined process, such as ingest, QC, or a delivery workflow, and map every step from start to finish. Then, count how many times a human touch is required during that process. When presented visually, this information can be particularly striking.

The experience of Hearst Networks EMEA, a Rally user, offers just one of many examples. The organization mapped out a “before” ingest workflow, which was found to include 16 separate manual touch points, each one a potential source of delay, error, or rework. (Spoiler: In orchestrating and automating ingest via Rally, the organization was able to reduce these touch points to just four.)

After documenting touch points, time is the next dimension to measure. Use a stopwatch. Literally. Measure how long specific tasks take right now, including wait times between steps. Capture real data about every task, from preparing assets to reviewing QC reports to communicating results. While these numbers don’t have to be perfect, they do need to be honest. With this information, you can identify a baseline for the effort required simply to keep the lights on.

Looking Beyond Time and Effort

Reducing touch points and realizing time savings are important steps in improving efficiency, but there are further aspects of your operations to consider. As you document the current state, look for other factors that affect the business more broadly. How many systems are involved in a single workflow? How many data sources need to be reconciled? How often does work get duplicated because information isn’t trusted or easily accessible?

Assess your organization’s flexibility, or the lack thereof. How quickly can your team respond when the business asks for something new, be it a delivery partner, format, or market? If changes require months of IT work or specialized resources, that rigidity has a real opportunity cost. Measuring adaptability can be harder than measuring minutes, but it’s often where you’ll find the greatest strategic value.

Once this information is gathered, it becomes the foundation for designing a better way forward. By analyzing where effort is concentrated, where delays occur, and where manual intervention adds little value, you can begin to reimagine the supply chain itself. The goal is not change for its own sake, but a more efficient, resilient process that reduces unnecessary steps, minimizes handoffs, and makes smarter use of automation. When the current state is clearly understood, it becomes much easier to define a future-state workflow that delivers better outcomes with less time, less effort, and fewer opportunities for error.

Pivoting With a Pilot Deployment

With all this information as a baseline, the next step is to test an alternative. By partnering with an expert in supply chain management, you can design and deploy a pilot project targeting a particular workflow. This approach is especially powerful when the pilot reflects real production conditions.

Unlike a demo, which can be too abstract to have a real impact on decision-making, a pilot allows you to take actual content and run it through a new workflow that mirrors how you would operate in production. When the pilot project proves the value of a workflow, it delivers tangible efficiency gains through a solution that can be readily implemented — and further optimized. In the event that the pilot does not prove the value of a new workflow, you can avoid investing time, effort, and money into actual implementation.

When testing with a pilot deployment, the key is to measure the same operational elements as you did in the “before” assessment. Pull out that stopwatch again. Time the same tasks and count the manual steps required. Then, compare your “before” and “after.”

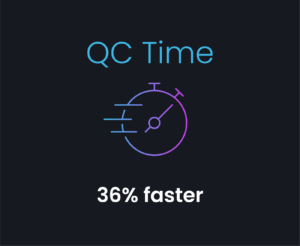

One media organization that deployed a Rally pilot project radically reduced time-to-QC — sometimes by more than 24 hours — by replacing manual checks of content delivery with automatic notifications. The organization then reduced the time required for a QC workflow from 25 to 16 minutes, realizing this 36 percent reduction by automating handoffs and presenting operators with only the information they need.

Similarly, automation of an ingest process allowed the organization to eliminate some manual steps altogether, shifting work to automated checks and exception-based handling, and thereby freeing operators to take on higher-value work. During this production pilot, the organization also identified three separate content ingest systems that could be retired.

Another Rally pilot delivered even more dramatic results. In measuring the “before” time required to move content between systems, the media organization found the process took 16 seconds. While a small number for a single process, this number grows exponentially when accounting for the hundreds or thousands of files that are accessed daily. When the organization shifted to a cloud-based environment, the concept of “moving” content disappeared entirely. The time effectively dropped to zero.

Another Rally pilot delivered even more dramatic results. In measuring the “before” time required to move content between systems, the media organization found the process took 16 seconds. While a small number for a single process, this number grows exponentially when accounting for the hundreds or thousands of files that are accessed daily. When the organization shifted to a cloud-based environment, the concept of “moving” content disappeared entirely. The time effectively dropped to zero.

Inspiring Confidence With Real-World Success

Detailed before-and-after analysis has led to success across very different organizations, where it helped to justify moving from legacy systems to a more automated, cloud-native orchestration model.

By measuring individual tasks and workflows, professionals within these organizations were able to show meaningful efficiency gains and make a data-driven case to leadership. Moreover, initial success with a single workflow served to create momentum for further change and optimization.

Following that first success, each organization expanded the transformation into other areas of their operations. With a foundation for cloud-enabled automation and orchestration already in place, they were able to realize compounding value through ongoing operational improvement.

The investment of time and effort in measuring legacy operations pays off both by surfacing inefficiencies and by providing targets for immediate action. It presents opportunity for media professionals, who can bring forward a well-reasoned, data-backed proposal for improving how the business operates. For some, it’s a career-defining step that demonstrates leadership, strategic thinking, and a clear connection between technology decisions and business outcomes.

Building Insight to Inform Action

Creation of a business case for media supply chain transformation can be a daunting task. But it’s not so complicated with the support of an experienced team. At SDVI we’ve worked alongside operations and technical teams to map workflows, design pilots, and measure results. We can help you to see what’s possible — and avoid common pitfalls.

So, if you’re facing a refresh, or simply questioning whether the way you work today is really the best it can be, start with one process. Measure it honestly. Test an alternative. Use the results to tell a clear story to internal stakeholders. Even a small first step can deliver outsized impact.

—

If you’re curious about what “before” analysis might look like for your organization, get in touch! We’d be happy to walk through a simple plan tailored for your business or use case.